Composting offers a safe, economical, and environmental friendly approach towards disposal of wastewater sludge generated from treatment plant processes. Due to shortage of available landfills and tighter air regulatory controls, these have turned the attention of engineers towards using composting which is looked upon as viable solution to overcome all that. Sludge compost systems are all operated using similar processes whereby organic materials will undergo different steps of biological degradation to produce stable humus which can be used as soil conditioner in agricultural field. In order to degrade and stabilize the sludge to composted material, it has to undergo stages of increased microbial activity coupled with rise in temperature caused by organic breakdown.

The are generally three different types of systems being built and used in wastewater treatment plants which are the 1) aerated static pile, 2) windrow system and the 3) enclosed vessel system. All of these systems operate on a similar concept that applies the same basic principles which starts by first adding bulking agent and amendment to the dewatered sludge. This is followed by aeration of the compost pile and finally curing the sludge before final disposal. To make things easier and explain into details, the amendment is actually organic materials such as sawdust, straw and hulls, added to the in feed stream so that it can reduce the bulk weight and make aeration (whether by mechanical or addition of air) becomes easier and more effective. Bulking agent on the other hand, serves as provider for structural support and increase porosity of the sludge so that air gets trap enough for microbial actions. Normally wood chips are selected to be used as bulking agent.

Aerated Static Pile

The system is made up of a network of perforated pipes which serves as an underground aerator unit generated by a blower with the mixture of sludge and bulking agent placed on top to cover the pipes. Typically the sludge is piled to a maximum height of 2 meters and the material is left to be composted for at least 25 to 30 days and to further extend additional 30 days time period for curing. Usually a layer of screened compost is often added at the last top most layers so that it can serve as a good insulator. For more effective composting effect, usually one has to ensure that there is sufficient air by making sure that there is enough blower unit assigned for piles of sludge mix. Nowadays, improved aerated static pile systems are developed to have the unit operated in a closed facility so that it can have better odor control.

Windrow

Windrow system is more or less similar like the aerated static pile except that the rows can be turned for better mixing to assist in the composting process. Usually this is considered more effective because it will lead to better mixing but however with the turning effect, this will release foul odors and thus windrow should be carried out in an enclosed system. Similar as in previous setup, windrow system will also need bulking agents and amendments added to the sludge so that composting effect can be more effective and the period can be anywhere between 20 to 25 days to complete one cycle.

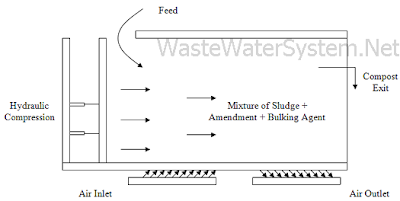

Enclosed Vessel System

Unlike windrow or static pile, in a vessel system, the composting is carried out in an enclosed container complete with proper process monitoring such as temperature and oxygen concentration. Generally using this system offers a faster turn cycle as the process can be controlled to the maximum rate. Furthermore since the whole composting is carried out in an enclosed vessel, this offers a better odor control and enhanced efficiency. However, one weakness in using this system is that only a low amount of sludge can be composted at any single time. There are basically two different types of this setup, one is the plug-flow and another is the dynamic type.