Sludge Volume Index (SVI) is a very important indicator that determines your control or rate of desludging on how much sludge is to be returned to the aeration basin and how much to take it out from the system. It actually serves as a very important empirical measurement that can be used as a guide to maintain sufficient concentration of activated sludge in the aeration basin whereby too much or too little can be considered detrimental to the system’s overall health. To put it in a lay man’s term, desludging or sometimes referred to as recycling sludge process, actually plays a very important role because the whole operation is needed to somehow strike a balance between removing dead or aged bacteria out of the systems or to determine how much goes back to the aeration pond.

SVI can actually be determined through use of standard laboratory test methods to come up with the results. Basically the procedure involves measuring the Mixed Liquor Suspended Solids (MLSS) value and also the sludge settling rate. A simple explanation on how it is carried out can be summarized below with accompanying images for easy reference and better understanding:

- Obtain sample of mixed liquor from the pond discharge pipeline and fill it to a 1 liter graduated measuring cylinder until the 1.0 liter marking.

- Allow it to settle for 30 minutes

- After the time period, read the marking to determine the volume occupied by the settled sludge and the reading is expressed in terms of mL/L and this is figure is known as the SV value.

- Next, for MLSS, there are actually two approaches to get the value. A conventional standard approach is by filtering the sludge, drying it and then weigh the second portion of the mixed liquid. However, this can be time consuming and a faster way is by using MLSS meter.

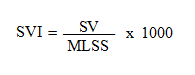

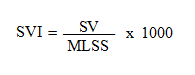

Value of Sludge Volume Index can then be calculated from the formula given here. Whereby,

SVI = Sludge Volume Index, mL/g

SV = Volume of settled solids in one-liter graduated transparent measuring cylinder after 30 minutes settling period, mL/L

MLSS = Mixed liquor Suspended Solids, ppm

SVI is a key factor when it comes to the clarifier design so that a clear wastewater discharge can be obtained without significant carry over of sludge. Basically what the value represents is the settling characteristics that have profound effect on the return rates and also the MLSS value. Typically a healthy sludge aeration pond basin should have the value registered within 80 to 150 mL/g and the MLSS concentration between 3000 – 5000ppm with the wastewater temperature less than 20degC. With this value in mind, generally the clarifier or settling basin has to be designed to accept higher solid loadings so that loss or carry over of sludge due to hydraulic displacement can be minimized.

Activated sludge pond is designed to allow adjustments on the amount of sludge return and also the take off rate. Regular desludging must be carried out to remove the aged sludge so that the new bacteria can regenerate and allowed to grow. As an experienced operator or engineers that operate the wastewater treatment plant, a tight control must be put in place to adjust the MLSS value to the desired concentration based on the set limit SVI to be used as a guide.

SVI = Sludge Volume Index, mL/g

SV = Volume of settled solids in one-liter graduated transparent measuring cylinder after 30 minutes settling period, mL/L

MLSS = Mixed liquor Suspended Solids, ppm

SVI is a key factor when it comes to the clarifier design so that a clear wastewater discharge can be obtained without significant carry over of sludge. Basically what the value represents is the settling characteristics that have profound effect on the return rates and also the MLSS value. Typically a healthy sludge aeration pond basin should have the value registered within 80 to 150 mL/g and the MLSS concentration between 3000 – 5000ppm with the wastewater temperature less than 20degC. With this value in mind, generally the clarifier or settling basin has to be designed to accept higher solid loadings so that loss or carry over of sludge due to hydraulic displacement can be minimized.

Activated sludge pond is designed to allow adjustments on the amount of sludge return and also the take off rate. Regular desludging must be carried out to remove the aged sludge so that the new bacteria can regenerate and allowed to grow. As an experienced operator or engineers that operate the wastewater treatment plant, a tight control must be put in place to adjust the MLSS value to the desired concentration based on the set limit SVI to be used as a guide.