Rotating Biological Contactors or better known as RBC System is mostly used for carbonaceous BOD removal and nitrification of effluent water. In a well-designed system, the RBC is considered to be superior in performance compared to a typical fixed-film setup. Among the advantages to it is that it has lower organic loading per mass of biological solids plus it also provides better control when it comes to short circuiting. To ensure that the unit serves its function, the design of a RBC system must be carefully planned out with factors such as staging of RBC units, effluent characteristics, loading criteria to be taken into account.

Effluent Characteristic

RBC systems are normally applied to serve secondary and advanced level of wastewater treatment plant. In fact, the characteristics must be comparable to a well-operated activated sludge process. The function of the RBC in this respect is to provide treatment to lower down wastewater BOD level and to aid in the nitrification process. In order to play important role towards denitification, the design of the rotating biological contactors must have the shaft totally submerged in the water.

Staging

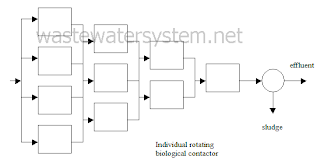

StagingStaging is perhaps another most important design criteria in order to come up with the best system. Staging basically refers to division and creation of individual compartments comprising RBC media. With different level of compartmentalization, this actually helps to promote growth of beneficial organisms among the baffles and as a result this, it will lower the concentration of organic concentration in the wastewater traveling different stages. Examples on the baffle arrangement can be seen in the attached diagram above.

Loading Criteria

Modern design of RBC systems is to focus on creating a unit that is based on either total BOD per unit of available surface area or soluble BOD per area expressed in lb SBOD/103ft2. Certain systems use another unit of measurement taken into accounts the nitrification factor instead as lbNH3/103ft2. Usually overloading is the main cause leading to poor operations and handling of the RBC systems and this is often contributed by defect in the design. The major problem that arises out of this, is the low Dissolved Oxygen (DO) condition and this will promote undesirable propagation of sulfate-reducing organism like Beggiatoa. In order to prevent overloading, several enhancements can be done on the design by either removing the baffles between first and second stages so that this helps to increase oxygen transfer to the wastewater.