Aeration system using pure oxygen can be applied towards activated sludge process in wastewater treatment plant. Basically there are different types of oxygen generators designed for today’s application and one of the two most commonly in use today is the Pressure Swing Absorption (PSA) System, which is meant to serve smaller capacity plant size that does not go beyond 30 Mgal/day. The other one is the Cryogenic Generation System.

The pressure swing absorption system relies on multi-bed setup that usually comprises a four-bed system to generate endless flow of high purity oxygen. The principle on the whole operation works by means of using absorber to separate out the oxygen from normal air at high pressure. Since it needs absorbent to continue to function, the absorbent has to be regenerated back again by using a blowdown system working under low pressure. The whole process eventually will alternate between those two steps, whereby once adsorption takes place, it must be followed later on by regeneration.

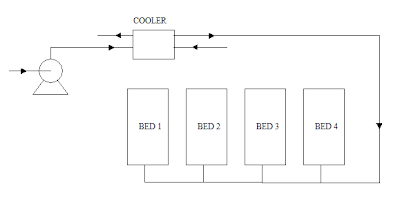

In order to explain the whole system going into more details, let’s look at the diagram above. First normal air will be fed to the system using a pump and before it enters the initial bed, it will be subjected to cooling using a heat exchanger. As it flows through the first absorber bed, oxygen will be released and as a result of that, the absorbent in the vessel will be filled with impurity. Once this happens, the airflow will be diverted by the system to another bed, while the previous one will now undergo regeneration process. The whole cycle will repeat itself with the second absorber bed while impurity that was collected in the first one will be purged out using oxygen by depressurizing it to atmospheric pressure. Once air again passes through the same bed, the system will be repressurized and the whole cycle starts all over again.

In order to explain the whole system going into more details, let’s look at the diagram above. First normal air will be fed to the system using a pump and before it enters the initial bed, it will be subjected to cooling using a heat exchanger. As it flows through the first absorber bed, oxygen will be released and as a result of that, the absorbent in the vessel will be filled with impurity. Once this happens, the airflow will be diverted by the system to another bed, while the previous one will now undergo regeneration process. The whole cycle will repeat itself with the second absorber bed while impurity that was collected in the first one will be purged out using oxygen by depressurizing it to atmospheric pressure. Once air again passes through the same bed, the system will be repressurized and the whole cycle starts all over again.Other alternative aeration facilities: Wastewater Blowers