In a wastewater treatment plant, it is important to control the Activated Sludge Process because this is the step whereby significant reduction in BOD and COD will take place. To ensure best performance, several control measures must be put in place such as ensuring that there is sufficient level of dissolved oxygen in the aeration tank and also adjusting the return and take off rate of activated sludge and waste sludge from the system.

Basically there are several parameters one can refer to as a guideline to find out whether the whole process is operating at peak performance. Mixed-liquor suspended solid (MLSS) is a common test value to determine whether the sludge is healthy or otherwise or whether it is too old or too young. This can be controlled based on the return and take-off rate as mentioned earlier. The F/M ratio (Food to Microorganisms) including the mean cell-residence time are another two parameters to look into as well. Refer to the guideline on how to determine the best sludge return rate.

There are different types of activated sludge processes designed and constructed depending on needs and flexibility. Here we shall discuss two of the most common system, one is the Plug-Flow Activated Process and another is the Contact Stabilization.

Conventional plug-flow activated sludge process

Conventional plug-flow activated sludge processConventional plug-flow schematic diagram is as shown above. Basically raw wastewater will first enter a primary clarifier whereby a certain percentage of sludge is left to settle before the wastewater is fed to the aeration tank. The influent will be mixed by use of diffused aeration system or mechanical aerator so that there is a uniform distribution of air throughout the whole tank. The treated water will overflow to another clarifier whereby the generated sludge amount will be distributed by either recycle back to the aeration tank or diverted out as waste sludge.

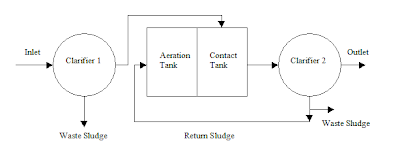

Contact stabilization activated sludge process

Contact stabilization activated sludge process